Unlike centrifugal pumps, positive displacement sliding vane pumps are dry-run capable, which means they do not need to be pre-primed, resulting in higher suction-lift capabilities

Introduction

For any industrial-pump operator, the accepted definition of suction lift as it relates to pump operation – “the vertical distance the pump can pull a liquid when the liquid source is located below the center line of the pump” – should be easy to grasp.

Actually achieving sufficient suction lift can, however, be a lot more complicated. The theoretical limit of suction lift for a pump at sea level is 33.5 feet (10.2 meters). This is because atmospheric pressure is constantly pushing down on the liquid at a rate of 14.5 psi (1.0 bar). When any pump operates, it works to decrease pressure at the inlet. If a pump achieves a “perfect vacuum” and drops the pressure to 0.0 psia it would theoretically allow the pump to pull a liquid 33.5 feet vertically.

This white paper will illustrate how positive displacement (PD) pump technologies, specifically those of the sliding vane variety, are able to outperform centrifugal-style pump technologies in overcoming changes in pressure when trying to achieve a proper amount of suction lift.

The Challenge

Suction lift is a common need in many industrial-pumping applications. Railcar unloading, fueling stations with underground storage tanks and chemical-processing plants are notable examples. The overriding challenge for these applications is that as the suction-lift requirement increases, the pump needs to decrease its inlet pressure in order to effectively pull the liquid into the pump. However, if that level of pressure becomes too low, the liquid can have a propensity to “cavitate.” Cavitation is defined as “the formation of bubbles within a liquid.” These bubbles can form when the pressure exerted on the liquid becomes low enough that the liquid starts to evaporate. As the bubbles go through the pump, pressure is rapidly applied to these bubbles, imploding them into liquid form. The rapid collapse creates a shockwave of energy in the liquid that will attack and damage the pump internals, resulting in inefficient operation and early failure.

In all high-suction applications, the pump will have to be primed before it can begin to operate safely and effectively. With that in mind, there are two types of priming that can be incorporated depending on the pump’s setup: wet or dry. (See sidebar for a closer look at dry priming.)

In general, wet priming occurs, as the term suggests, when there is residual fluid left in either the piping or the pump itself. Any fluid that remains in the piping will have surface tension or the fluid may be intentionally trapped within the piping or pump via use of a foot or similar valve. This enables the inlet to be “wetted” with liquid before operation begins and this “wet suction lift” condition will improve the pump’s overall suction-lift capabilities. It also makes priming the pump easier and offers such benefits as the ability to produce up to five more feet of suction lift at startup and to pump liquids with higher viscosities.

For many years, centrifugal pumps have been the most commonly used technology in industrial liquid-transfer applications even though their operators must pre-condition, or “prime,” centrifugal pumps before they can begin operating them, which is a process that is labor-intensive, time-consuming, cost-prohibitive and, quite frankly, annoying. In other words, the volute of a centrifugal pump must contain some liquid as it begins to operate because if it is allowed to “run dry” the pump will overheat, which can result in mechanical-seal failure.

A second way that operators can try to make centrifugal pumps work in this type of application is through the use of a self-priming centrifugal pump. These pumps feature a reservoir that continues to hold liquid when the pump is not operating, and the level of this liquid in the reservoir must be manually maintained as it diminishes after initial operation. When the pump begins to operate, the liquid in the reservoir is circulated through the pump with this circulation forcing any air that is inside the pump to move through the suction piping and out of the discharge port. Only once all of the air has been removed can the product begin to flow safely. Note, though, that even self-priming centrifugal pumps cannot run dry.

Once the centrifugal pump is properly primed, it can create suction lift, but the extra time and (in some cases) cost needed to do so can lead to production and bottom-line inefficiencies that can hamper the overall performance and cost-effectiveness of the pumping operation.

Considering Dry Suction Lift

As opposed to wet suction lift, which uses residual liquid or a mix of vapor/air to prime the pump, dry suction lift relies on a dry vacuum to pull liquid from a spot that is lower than its inlet port. In order to do this, the pump must be capable of producing enough vacuum to pull the liquid up to the pump’s inlet port. Some pump technologies, like positive displacement sliding vane, are able to run dry and can therefore operate safely until the pump has become “self-primed,” at which point it will begin operating normally.

When you do encounter a situation where the lines are completely dry at startup, it is recommended that the pump’s internals get as wet as possible as quickly as possible. When dry-run operation is not preferred or, in some cases, possible, some pump technologies – such as centrifugal, screw, progressive cavity and lobe – may require the addition of a priming mechanism, typically a vacuum unit, compressor or diaphragm, to the pump that is designed to introduce liquid to the pump quickly, which makes the pump “self-priming.” However, the addition of a priming mechanism does make the pump’s operation moderately more complicated since the priming liquid needs to be manually added to the mechanism. This also adds cost to the operation of the pump.

So, while it may not be the best scenario, achieving dry suction lift in a sliding vane pump is possible and easier to achieve than with competing pump technologies. The challenge to the operator is designing a pumping system that does not require dry running to achieve suction lift to occur very often or for extended periods of time.

The Solution

A reliable alternative to centrifugal pumps in high suction-lift applications is the PD sliding vane pump. When the piping is flooded via wet priming, a PD pump can create a wetted suction-lift value of approximately 25 feet (7.6 meters), while the maximum actual wetted suction lift for a centrifugal pump is generally up to 15 feet (4.6 meters).

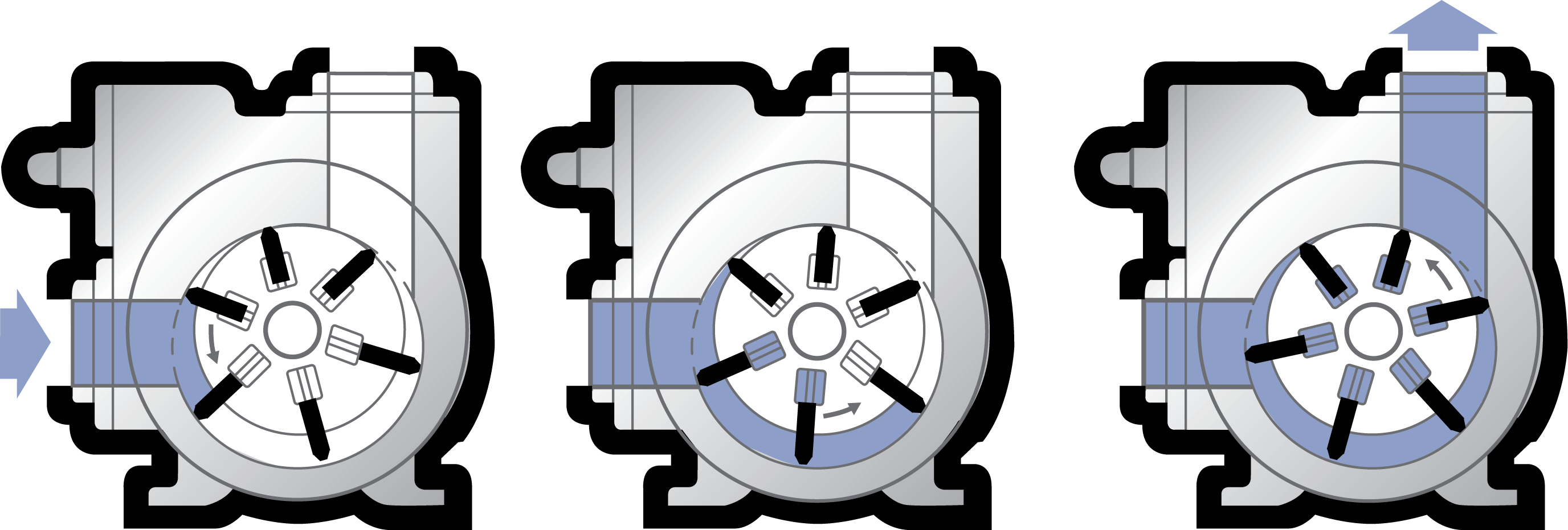

The secret to the sliding vane pump’s success in creating high suction-lift values is found in its unique design and method of operation. Sliding vane pumps have a number of non-metallic vanes. When the pump driver turns the rotor, a combination of forces – centrifugal (pump speed), mechanical (push rods) and hydraulic (liquid pressure) – force the vanes out of their slots and into the walls of the pump casing, creating a seal between the two. As the vanes rotate in the cylinder, a vacuum is created at the inlet of the pump. Because sliding vane pumps can run dry, there is no risk of overheating or excessive cavitation within the pump as the pump creates suction.

Additionally, during the priming process, any air or vapor that is in the pump or piping needs a release as a pressurized discharge will prevent the pump from priming. In this instance, sliding vane pumps can be outfitted with an air-release valve or control valve that is opened to the supply vessel, which allows the dissipation or any air or vapor that is present.

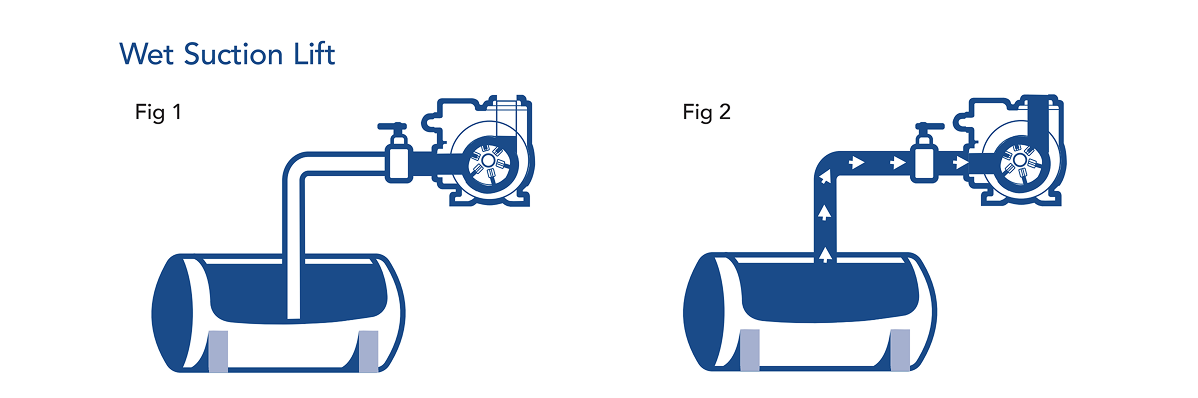

This illustration shows how the concept of dry suction works. With the sliding vane pump located above the liquid source (Fig 1), the pump’s “self-priming” capability allows it to create a vacuum that can pull the liquid up toward the pump chamber (Fig 2).

Taken together, optimized sliding vane pump operation in these areas will result in a liquid-transfer application that is able to meet consistently, efficiently and safely all of the application’s suction-lift requirements.

Conclusion

The ability to create suction lift is a foundational requirement in many common industrial liquid-transfer applications. Some technologies that claim to have suction-lift capabilities may also be inadequate for the job if they are unable to run dry. In this case, these pumps will need to be pre-primed before beginning to operate, which results in added system and labor costs, complexity and hassle for the operator.

The ultimate solution in high suction-lift applications is positive displacement sliding vane pumps. Specifically, Blackmer® Sliding Vane Pumps can easily produce 25 feet (7.6 meters) of suction lift with no need for pre-priming or the use of additional system equipment and components, not to mention the additional benefits they offer like lower installation and operating costs, consistent flow rates and easy maintenance. For these and many more reasons, sliding vane pumps continue to grow market share in industrial applications, at the expense of centrifugal-pump technologies that require pre-priming that makes them much more expensive and complicated to operate, while still not being able to achieve an optimized level of suction lift.

To read the full white paper, please click here.

About The Author

Chris Hordyk is an Application Engineering Manager for Blackmer, Grand Rapids, MI, USA. He can be reached at chris.hordyk@psgdover.com. Blackmer is a leading global brand of sliding vane, internal gear, regenerative turbine and centrifugal pump, and reciprocating compressor technologies for the transfer of liquids and gases. Blackmer is a product brand of PSG, a Dover company, Downers Grove, IL, USA. PSG is comprised of several leading brands, including Abaque, All-Flo, Almatec, Blackmer, Cryo-Mach, Ebsray, em-tec, Griswold, Hydro, Malema, Mouvex, Neptune, PSG Biotech, Quantex, Quattroflow and Wilden. For more information on Blackmer or PSG, please go to psgdover.com/blackmer or psgdover.com.