In industrial applications, viscosity is defined as a liquid’s “resistance to flow at a given temperature,” with thinner liquids (water, benzene, mercury, etc.) having lower viscosities and thicker liquids (honey, ketchup, peanut butter, etc.) having higher viscosities. In other words, low viscosity liquids have less resistance to flow than high viscosity liquids when they are subject to shear stress, which is the amount of force the liquid can absorb before it begins to deform or deteriorate.

Multiple factors can affect a liquid’s viscosity level during the pumping process. The most common of these are increases in temperature or pressure, along with the introduction of solids into the liquid.  Among these, temperature changes can have the greatest effect on viscosity levels. Generally, an increase in temperature will make the liquid thinner, while a decrease will make the liquid thicker. What, then, is the best type of pump technology to handle liquids that are naturally high in viscosity or subject to viscosity-altering temperature changes during the pumping process? In this case, positive displacement (PD) pumps are the best choice as they are “viscosity flexible.” In other words, they experience no reduction in performance as the liquid’s viscosity level increases or decreases. This applies to liquids with viscosities ranging from ultra-thin (0.2 cP) to ultra-thick (200,000 cP).

Among these, temperature changes can have the greatest effect on viscosity levels. Generally, an increase in temperature will make the liquid thinner, while a decrease will make the liquid thicker. What, then, is the best type of pump technology to handle liquids that are naturally high in viscosity or subject to viscosity-altering temperature changes during the pumping process? In this case, positive displacement (PD) pumps are the best choice as they are “viscosity flexible.” In other words, they experience no reduction in performance as the liquid’s viscosity level increases or decreases. This applies to liquids with viscosities ranging from ultra-thin (0.2 cP) to ultra-thick (200,000 cP).

On the other hand, rotodynamic pumps, i.e., centrifugal pumps, will see a degradation in their performance if the liquid’s viscosity drops below 1 cP or rises above 1 cP. This is because centrifugal pumps have a single optimized operational best efficiency point (BEP) and can fail when operating outside of this narrow range. It is unfortunate for centrifugal pumps that most liquid-handling applications must confront a wide range of operating conditions, including fluctuations in viscosity, as well as pressure, flow rate and tank level.

Within the Blackmer® pump family, both sliding vane and gear pump technologies excel when handling liquids with wide performance ranges, such as fluctuating viscosities, which enables them to offer enviable operational flexibility with sustained optimal performance when compared to centrifugal pumps.

Specifically, Blackmer offers its MAGNES Series Sliding Vane Magnetic Drive Pump for demanding high viscosity applications where mag-drive operation and seal-less technology are preferred. The design of the MAGNES pump is based on the Blackmer NP Series Sliding Vane Pump, which is constructed to excel in pumping applications that feature changing viscosities, temperatures and pressures. The MAGNES pump boasts several important design features that enable it to reliably handle high-viscosity liquids, including optimized porting, clearances, bushings, rotor design and vane material. These design features and operational advantages allow the MAGNES pump to transfer liquids with viscosities ranging from 1 cP to 2,200 cP, or from water to glucose.

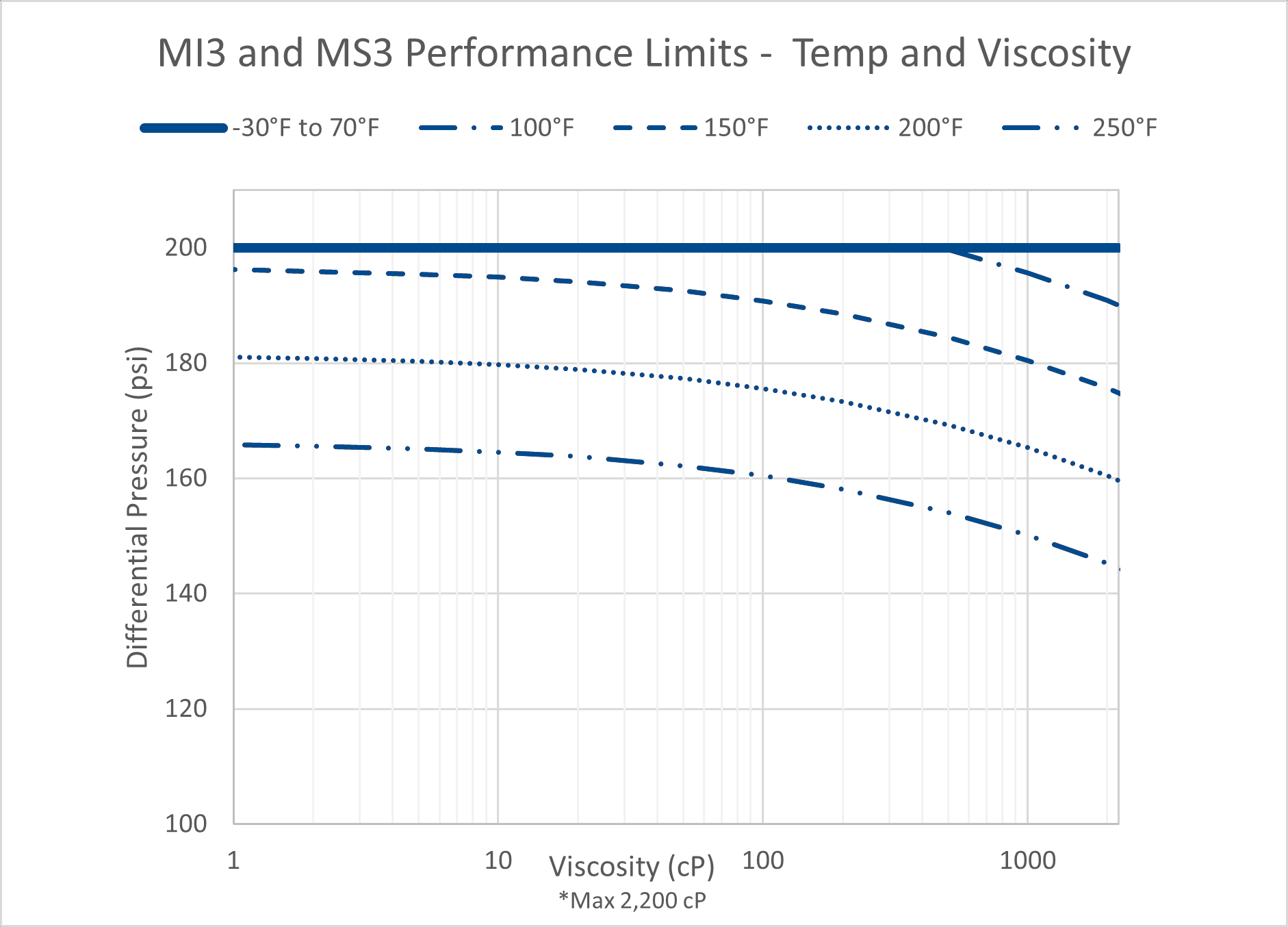

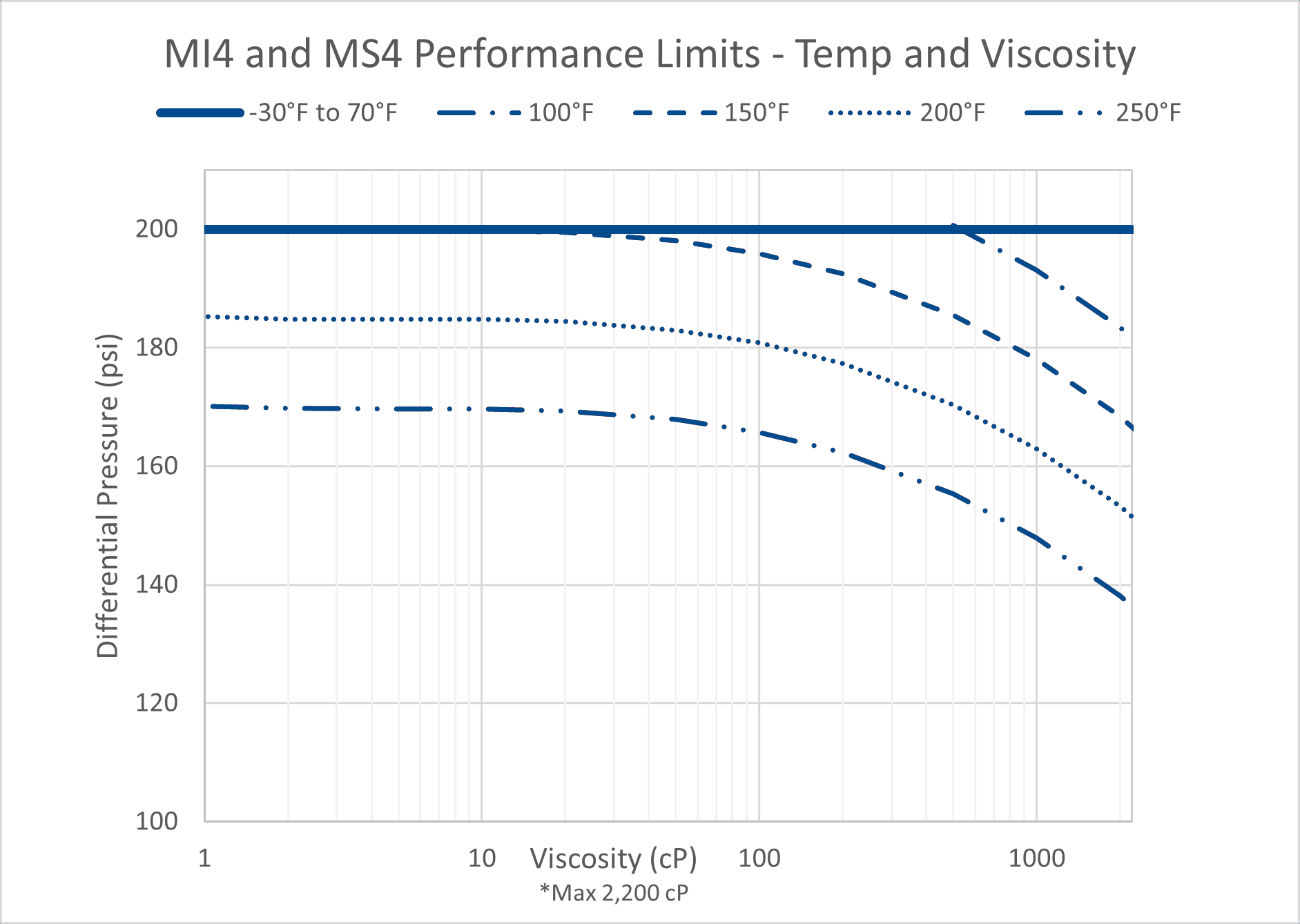

MAGNES pumps can handle viscosities up to 2,200 cP. The maximum differential pressure varies based on the temperature of the process fluid.

MAGNES pumps are available in 3- and 4-inch models, constructed from either ductile iron or stainless steel, with flow rates of up to 520 gpm (1,968 L/min). While operating at a speed of just 400 rpm, MAGNES generates the same pressures and flow rates of other pumps that operate at 3,600 rpm, with no excessive heat buildup or component wear. As a true self-priming pump, MAGNES pumps will never require pre-flooding at startup, and they are made for continuous-duty operation. MAGNES also boasts full curve and system-performance capabilities, unlike any other mag-drive pump available.

While many pump users require transferring liquids with a variety of viscosities within a common pumping system, centrifugal pump technology has proven to be a suboptimal choice in these applications. Alternatively, Blackmer MAGNES pumps feature designs and operational capabilities that enable them to deliver more consistent performance and reliability over a wide range of liquid viscosities.

Lit code: atk0210-056 06/25