Dry run seems simple – “operating a pump without any liquid” – but its consequences are anything but.

Why Competitor Pumps Fail to Run Dry

CENTRIFUGAL PUMPS

For centrifugal pumps, dry-run operation results in one of three catastrophic outcomes: 1) bearing failure, 2) magnet coupling failure and/or 3) containment failure. Each failure causes rotating elements to seize, resulting in liquid leaks. The root cause is the high rotational speeds of centrifugal pumps, often exceeding 3,600 rpm. High rotational speeds cause aggressive friction and heat within rotating elements, including the hardened bushings.

Centrifugal manufacturers attempt to prevent bearing failure by offering various bushing material options, but each option is vulnerable to dry-run failure:

- Silicon carbide cracks within seconds of beginning dry-run operation and requires the use of power monitoring systems to turn the pump off in the seconds before failure.

- Protective coatings applied to traditional bushings provide a short cumulative wear allowance that depletes over time, is not renewable and quickly leads to failure.

- Composite blends offer self-lubricating benefits but wear quickly and sacrifice useful life at the fast rotational speeds of centrifugal pumps, leading to failure.

Magnet couplings can fail due to two primary causes: 1) eddy-current overheating (with metallic containment shells) and 2) aggressive decoupling action resulting from bushing failure.

Containment breaches can occur due to two factors:

1) rapid contact speeds between internal components and 2) likely bearing failure. If the couplings don’t fail first, rotating elements wear against the containment shell until it wears enough for a costly and hazardous liquid breach to occur.

GEAR PUMPS

For gear pumps, dry-run operation permanently damages internal components because internal gears, idlers, bushings and pins are contacting elements that wear and crack during dry-run operation. Soon, material wear causes decreased performance, accelerated wear and eventual breakdown.

OTHER PUMPS

Some pump styles utilize coated bushings that enable dry-run operation, but they deliver only approximately two hours of cumulative dry-run time. This makes it difficult to determine how much of the allotted dry-run time has actually elapsed, with no warning given for when the dry-run time allowance will be exhausted.

Dry-Run Capable with ZERO Impact on Performance

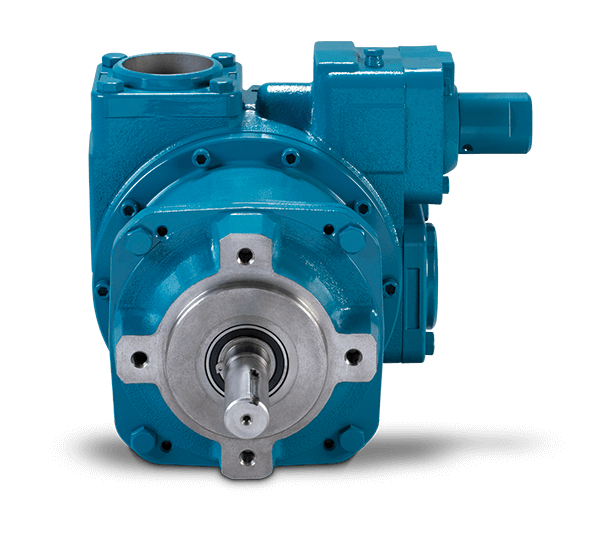

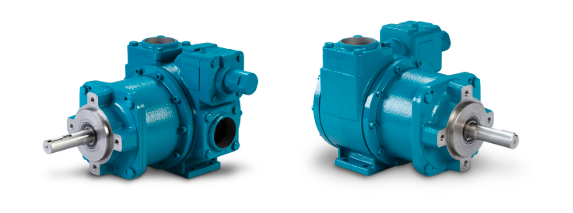

A permanent solution is the rotary sliding vane pump, which uses non-metallic, self-lubricating components capable of indefinite dry-run operation. Specifically, the Blackmer® MAGNES Series Sliding Vane Magnetic Drive Pump offers an innovative alternative to centrifugal and gear pumps, as well as mag-drive pumps.

Key design differentiators within MAGNES are 1) its reduced operational speed and 2) the utilization of a proprietary non-metallic containment shell that prevents eddy-current overheating.

MAGNES has no dynamic seals, making it ideal for difficult-to-seal liquids that are too valuable or hazardous to leak. Even during dry-run operation, MAGNES can pull a vacuum, strip lines and create suction lift exceeding 25 feet (7.6 meters) while working continuously during and after any planned or unanticipated dry-run events.

While operating at a speed of just 400 rpm, MAGNES generates the same pressures and flow rates as other pumps that operate at 3,600 rpm, with no excessive heat buildup or component wear. As with all positive displacement pumps, the MAGNES sliding vane pump will also handle changes in system conditions such as pressure and viscosity without significant change to performance.

As a true self-priming pump, MAGNES will never require pre-flooding at startup and is well-suited for continuous-duty operation. Since MAGNES has no cumulative dry-run time limit, it provides confidence that any type of dry-run event will not result in catastrophic pump failure.

The MAGNES is available in 3- and 4-inch models in either ductile-iron or stainless-steel construction with flow rates up to 520 gpm (1,968 L/min).

The MAGNES is available in 3- and 4-inch models in either ductile-iron or stainless-steel construction with flow rates up to 520 gpm (1,968 L/min).Common Contexts For Dry Run

Unanticipated Dry Run

Caused by operator error, faulty instrumentation or system transients

Competing magnetic-drive pumps are damaged catastrophically from dry run and require expensive monitoring and control systems. These monitoring systems are unreliable, as they often result in unnecessary service trips. If ignored, they also leave systems vulnerable to inevitable dry-run failure.

MAGNES offers peace-of-mind reliability with no cumulative dry-run time limit.

Self-Priming

Required when a pump isn’t pre-flooded (i.e., suction lift or batch process)

- Self-priming centrifugal pumps are cost-prohibitive and have limited capabilities: <250 gpm (950 L/min) and <250 feet (75 meters) at 100 psi (6.9 bar). Furthermore, they are not true self-primers, as they require an initial fill of the pump’s suction cavity to operate.

- Internal gear magnetic-drive pumps suffer from material galling.

- MAGNES offers exceptional suction lift that can exceed 25 feet (7.6 meters).

Line Stripping

Required when liquid needs to be recovered (i.e., cost savings or batch process)

- Self-priming centrifugal magnetic-drive pumps cannot push air. Therefore, they cannot line strip.

- Internal gear magnetic drive pumps suffer from material galling.

- MAGNES offers exceptional product recovery and liquid withdrawal from piping and hoses when operating in both forward and reverse rotation.

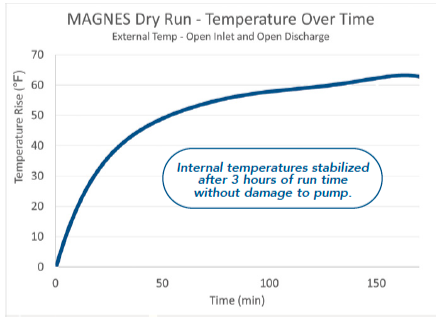

MAGNES: TESTED AND PROVEN FOR MAXIMUM DRY RUN PERFORMANCE

The operational factors that allow the MAGNES to have fewer dry-run limitations than competitive technologies are:

- Non-magnetic containment-shell construction

- Low bearing loads due to non-cantilevered rotor design

- Self-lubricating vanes and sleeve bearings

- Lower running speed for less friction heat during dry-run operation

To validate its dry-run performance, Blackmer put MAGNES to the test.

Testing Details

The MAGNES was specifically tested to measure its superior resilience to dry-run conditions. After two hours, the temperature stabilized to a near-steady state. The test conditions were as follows:

- Stainless steel 3” MAGNES with Duravanes installed

- Simulated empty supply tank with open inlet and open discharge

- Speed = 640 rpm

- Run time > 3 hours

- Temperature measured near the bushing locations where dry-run damage is typically seen

The test results support the conclusion that the MAGNES can dry run for extended periods of time with minimal risk of damage or failure. Additionally, after the dry-run test was completed, the pump was disassembled, and an inspection showed no indication of excessive wear.

To read the full article, please click here. To learn more, visit us at blackmer.com/MAGNES-DryRun.