While hygienic manufacturers face many daily challenges, the two most prominent are ensuring that finished products meet predetermined levels of safety and quality. This is critical because whether the operation produces food, beverages, pharmaceuticals or personal-care products, a product recall can cost the manufacturer a tremendous amount in tangible (maintenance, repair and replacement costs) and non-tangible (damaging loss of brand reputation) ways. Therefore, any pumping equipment that comes in contact with raw materials or finished hygienic products must meet stringent standards for purity.

Avoiding the product contamination that can lead to costly and debilitating product recalls was the driving force behind the development of the Wilden® Saniflo™ Hygienic™ Series (HS) Air-Operated Double-Diaphragm (AODD) Pump. The Saniflo HS’s numerous design enhancements, including a free-draining flow path, multiple valve options, Tri-Clamp® fittings and use of the proprietary Pro-Flo® SHIFT Air Distribution System (ADS), allow it to meet or exceed all 3A, FDA CFR 21.177, USP Class VI, 1935/2004/EC, ATEX and CE hygienic-manufacturing regulatory requirements.

This level of hygienic performance is further optimized when the Saniflo HS pump is outfitted with Wilden’s patented Pure-Fuse Integral Piston Diaphragm (IPD), which is a full-stroke IPD specifically engineered for hygienic sanitary applications that require high cleanability.

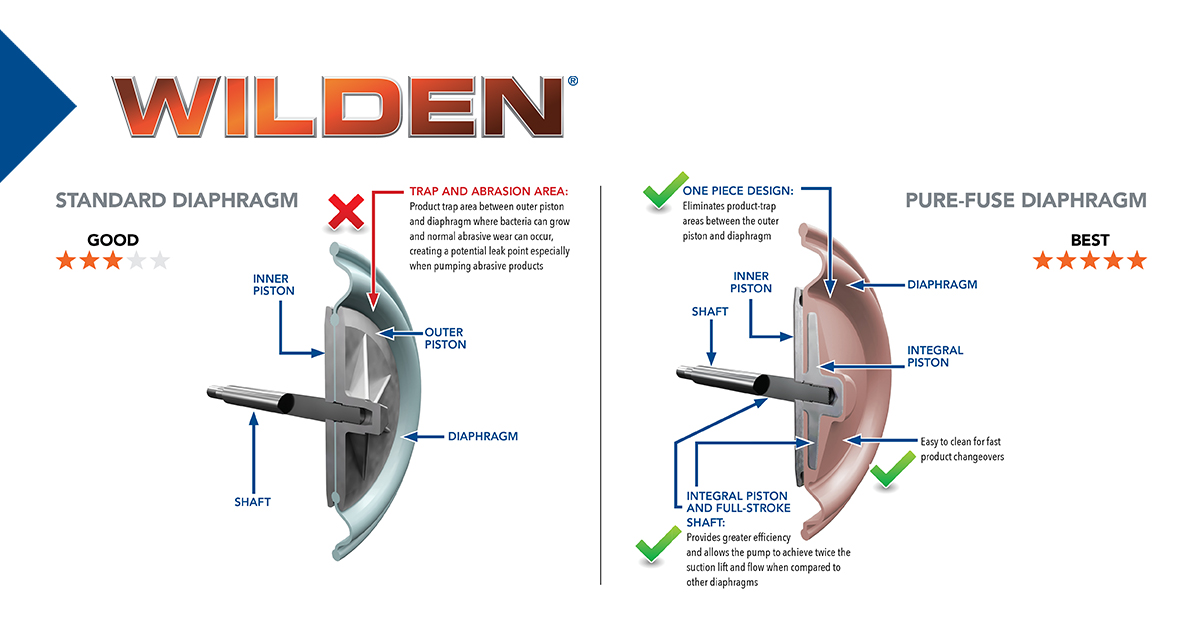

While conventional diaphragms that have an outer piston – which can be a trap area for product to nest and bacteria to grow – can compromise the integrity of the finished product, the construction of Pure-Fuse IPDs combines food-grade plastics and elastomers with a stainless-steel core that eliminates the need for an exposed outer piston. This revolutionary one-piece design encases the outer piston within the diaphragm material, resulting in a single continuous surface with no trap areas that can harbor bacteria. The design also eliminates the piston-diaphragm contact area where normal abrasive wear can cause the creation of leak points (which leads to costly product loss).

In conjunction with these design enhancements, Pure-Fuse IPDs can improve pump performance when compared to other competitive pumps and diaphragms; in many instances, the Pure-Fuse IPD can increase the Saniflo HS pump’s flow and suction-lift capabilities by up to 100% . Additionally, no adhesive is used in the Pure-Fuse diaphragm’s construction, which makes them a perfect choice for hygienic product-handling applications. Finally, Pure-Fuse IPDs have a price point that can be 50% lower than comparable PTFE-laminate diaphragms.

In the end, when Pure-Fuse IPDs are combined with the numerous capabilities of Saniflo HS pumps, you have an AODD pump that improves overall cleanability, extends uptime, provides superior product containment, enhances operational efficiency, and simplifies cleaning and maintenance.

Learn more about Pure-Fuse Diaphragms.

Learn more about Saniflo HS Pumps.