Producers of paint and coatings face a formidable challenge: balancing growing demands, maximizing uptime performance and adhering to stringent environmental standards – all while managing costs.

To achieve the highest global quality standards, paint and coatings manufacturers must harness the power of robust pumping technology. However, not just any pump will do.

Manufacturers require pumps that deliver exceptional flexibility and performance in the form of reliability, energy efficiency, product-loss prevention and environmental protection.

Here’s how Wilden® – the inventor of air-operated double diaphragm pump (AODD pump) technology – can help.

Why Are AODD Pumps A Reliable Choice for Paints and Coatings?

While many pump technologies have been tested in paint and coatings applications, AODD pumps have been shown to excel in a variety of processes, including:

- Resin transfer

- Solvent transfer

- Filtration

- Loading/unloading

In addition to a unique design that ensures total product containment, AODD pumps also deliver paint and coatings manufacturers a long list of features:

- Self-priming and run-dry capabilities

- Seal-less, shear-sensitive operation

- Portable functionality

- Easy to install and simple to maintain

- Longest Mean Time Between Failure (MTBF)

However, in today’s highly competitive paint and coatings environment, manufacturers face growing operational difficulties due to rising demand in developing markets and a recovery in North American needs. What does that mean for manufacturers?

More than ever, it remains essential that manufacturers choose AODD pump technology that can reduce energy usage and control costs without compromising performance.

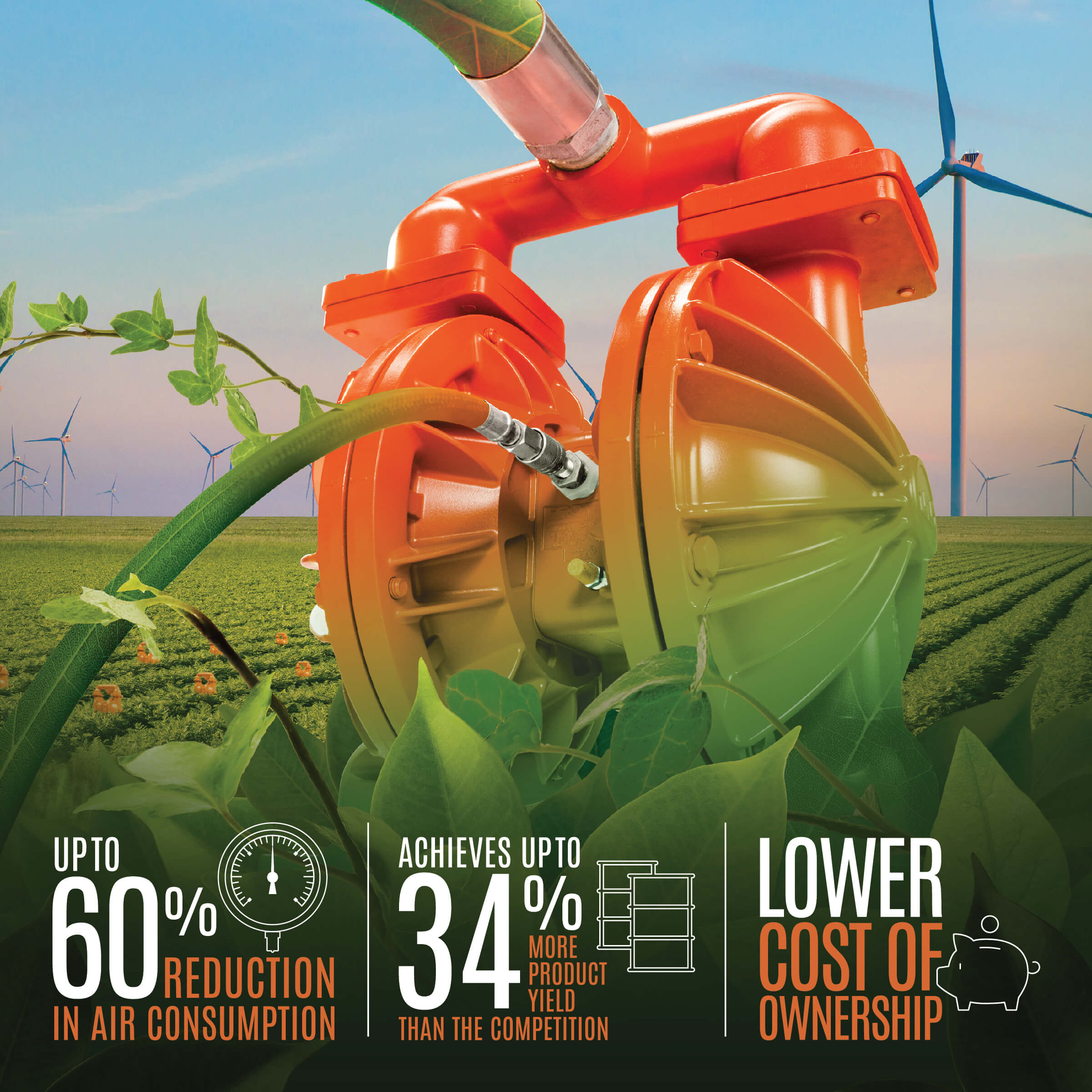

Maximize Energy Efficiency with Wilden Pro-Flo® SHIFT Series

Featuring the industry’s premier air distribution system (ADS), the Wilden® Pro-Flo® SHIFT Series Pump restricts the air flow into the air chamber as each pump stroke nears completion. This automatically optimizes air consumption and eliminates overfilling of the air chamber, which:

- Allows up to a 60% reduction in air consumption

- Achieves up to 34% more yield than the competition

- Leads to a lower cost of ownership

Providing operational flexibility for paint and coatings manufacturers, the Pro-Flo SHIFT Series is offered in both bolted and clamped configurations.

- Clamped metal pumps have minimal hardware, allowing for easy disassembly and making them ideal for applications with excessive coating that require frequent cleaning.

- Bolted metal pumps, which offer better containment than clamped models, are suitable for applications where aggressive solvents and dangerous chemicals pose a safety risk.

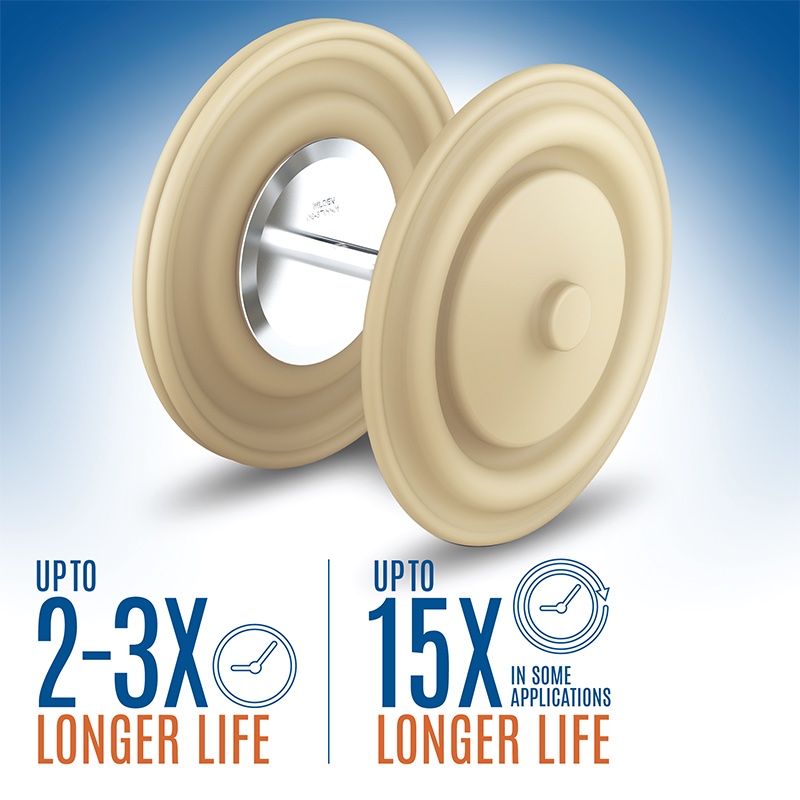

Increase Durability with Wilden Chem-Fuse™ Diaphragms

The Wilden Chem-Fuse™ Integral Piston Diaphragm (IPD) stands out as a dynamic alternative in challenging paint and coatings applications where conventional diaphragms falter. Its innovative one-piece construction delivers exceptional durability, significantly extends flex life and streamlines cleaning procedures.

With Wilden Chem-Fuse diaphragms inside your AODD pump, you can:

- Eliminate outer piston abrasion

- Increase diaphragm wear life by 2 to 15 times

- Experience less downtime and more uptime

- Enjoy the peace of mind of long-lasting performance

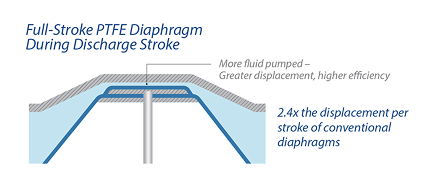

Achieve Peak Performance with Wilden Full-Stroke PTFE Diaphragms

When your paint and coatings applications require maximum performance and the highest level of containment, Wilden Full-Stroke PTFE Diaphragms are the better option.

Because PTFE is chemically inert, PTFE Full-Stroke Diaphragms are non-reactive to most aggressive chemicals and solvents that are used in paints and coatings manufacturing, which helps:

- Provide greater productivity

- Increase displacement per stroke

- Enhance suction lift

- Improve flow rates

Ready to Mix Efficiency, Durability and Performance Into Your Paints and Coatings Operation?

In the paint and coatings industry, where operational efficiency, product integrity and environmental responsibility are non-negotiable, manufacturers need technology that does more than just move fluids. They need simple, efficient and reliable AODD pumps and diaphragms that enhance every facet of their operation.

By investing in the Wilden Pro-Flo SHIFT Series, Chem-Fuse Integral Piston Diaphragms and Full-Stroke PTFE Diaphragms, manufacturers can confidently meet rising global demand while reducing operational costs.

To learn more about how Wilden can help you increase uptime and achieve long-term cost savings, please contact your local distributor or click here to fill out our contact form.