Single-use flow paths are meant to make bioprocessing simpler. Pre-sterilized assemblies arrive ready to hang, connect and run. In reality, anyone who has stood over a skid during start-up knows there is a quiet troublemaker in the line: air.

Tiny pockets of air trapped during setup and transfer can slip through sight checks and only reveal themselves when you see a noisy pressure trace or a chromatography step that refuses to behave. In downstream operations, bubbles can disrupt packed beds, trigger pressure spikes, affect filling accuracy and chip away at overall batch confidence.

That is exactly the problem PSG Biotech set out to tackle with its new BioPro® FlowMCP variant: the BioPro® FlowMCP plus (1-4 channels). This non-invasive ultrasonic flow meter combines real-time flow measurement with air-in-line detection on single-use tubing.

.png?sfvrsn=8173b04f_1)

Why Bubbles Matter

In packed chromatography columns, air bubbles can create channels in the resin bed, leading to uneven flow paths, zone broadening and loss of resolution. In ultrafiltration and diafiltration, entrained gas can show up as pressure fluctuations and unstable transmembrane pressures, speeding up membrane fouling. On aseptic filling lines and buffer transfers, bubbles can undermine dose accuracy and trigger unnecessary alarms.

Detecting bubbles early – ideally at priming and during critical transfers – is a pragmatic way to protect yield and quality without re-engineering the entire process.

Non-Invasive Clamp-On Technology

Clamp-on ultrasonic sensors sit around the tube rather than inside the flow path. Two transducers send and receive ultrasonic pulses through the tube wall; the transit time difference of those signals is proportional to the volumetric flow rate and thus serves as a basis to calculate the flow value.

In combination, PSG Biotech's BioPro® FlowMCP and BioPro® Clamp-On SL sensors provide non-invasive flow measurement on flexible tubing with no product contact and no additional wetted materials to qualify. The measurement method does not introduce extra shear stress, protecting shear-sensitive cells and proteins. Because the hardware is reusable, it can be moved between lines and batches, balancing flexibility, cost and sustainability.

BioPro Clamp-On with Bubble Detection

The new BioPro® FlowMCP variant builds on this platform and adds dedicated air-in-line monitoring on single-use tubing. Following the same proven transit-time principle as the BioPro® FlowSU flow meter, it enables:

- Priming verification: Confirm that lines are fully filled and residual air is flushed out before starting sterile operations

- Continuous monitoring: Track air during perfusion feeds, chromatography loading, UF/DF loops and buffer transfers

- Flexible deployment: Relocate the same sensor to different sections of the skid in development labs or GMP suites

For engineers, this combination of flow and bubble visibility de-risks operations already in place without requiring unfamiliar hardware.

Complementary Solutions: In-Line and Coriolis Options

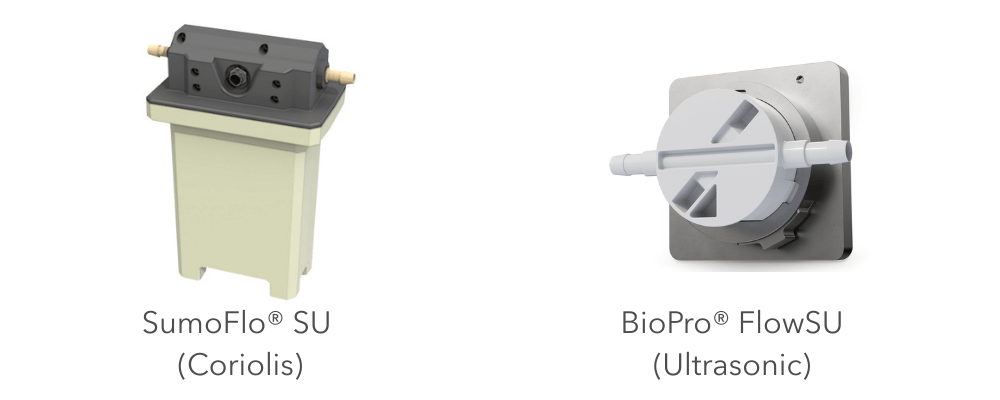

Clamp-on is not the only option. The BioPro® FlowSU flow meter combines a disposable in-line flow sensor with integrated bubble detection, ideal for pre-engineered single-use assemblies with a clear scale-up path.

Where mass flow accuracy is critical, SumoFlo® single-use Coriolis flow meters deliver high-precision measurement independent of fluid properties, with smart alarms for bubbles, high/low flow, and overflow conditions – particularly valuable in bulk filling operations.

Choosing the Right Technology

BioPro® Clamp-On for flexible, non-invasive monitoring during priming checks, media feeds and transfers where you need early warning without breaking the sterile path.

BioPro® FlowSU for pre-engineered assemblies with built-in flow and bubble detection, minimal setup time and manufacturing scale-up.

SumoFlo® for highly accurate mass flow in high-value steps like final fill and bulk filling, with smart alarms for flow deviations.

The right answer is often a combination: clamp-on sensors support flexible development and troubleshooting, while in-line ultrasonic and Coriolis flow meters underpin steps requiring the tightest control.

Making Bubble Detection Standard Practice

As single-use systems become more complex, the impact of undetected bubbles becomes harder to ignore. They can affect resin performance, membrane life, fill accuracy and the time teams spend investigating noisy process data.

Adding clamp-on bubble detection to critical flow paths is a small step compared with the cost of a lost batch. By pairing BioPro® clamp-on products with in-line FlowSU sensors and SumoFlo Coriolis meters where needed, bioprocess teams can see what is actually happening inside their single-use systems – and act before air becomes a problem.