Mouvex G-FLO Eccentric Disc Pumps Vs. Twin Screw Pumps

Optimize Performance in Your Process

Eliminate Compromise, Enhance Performance

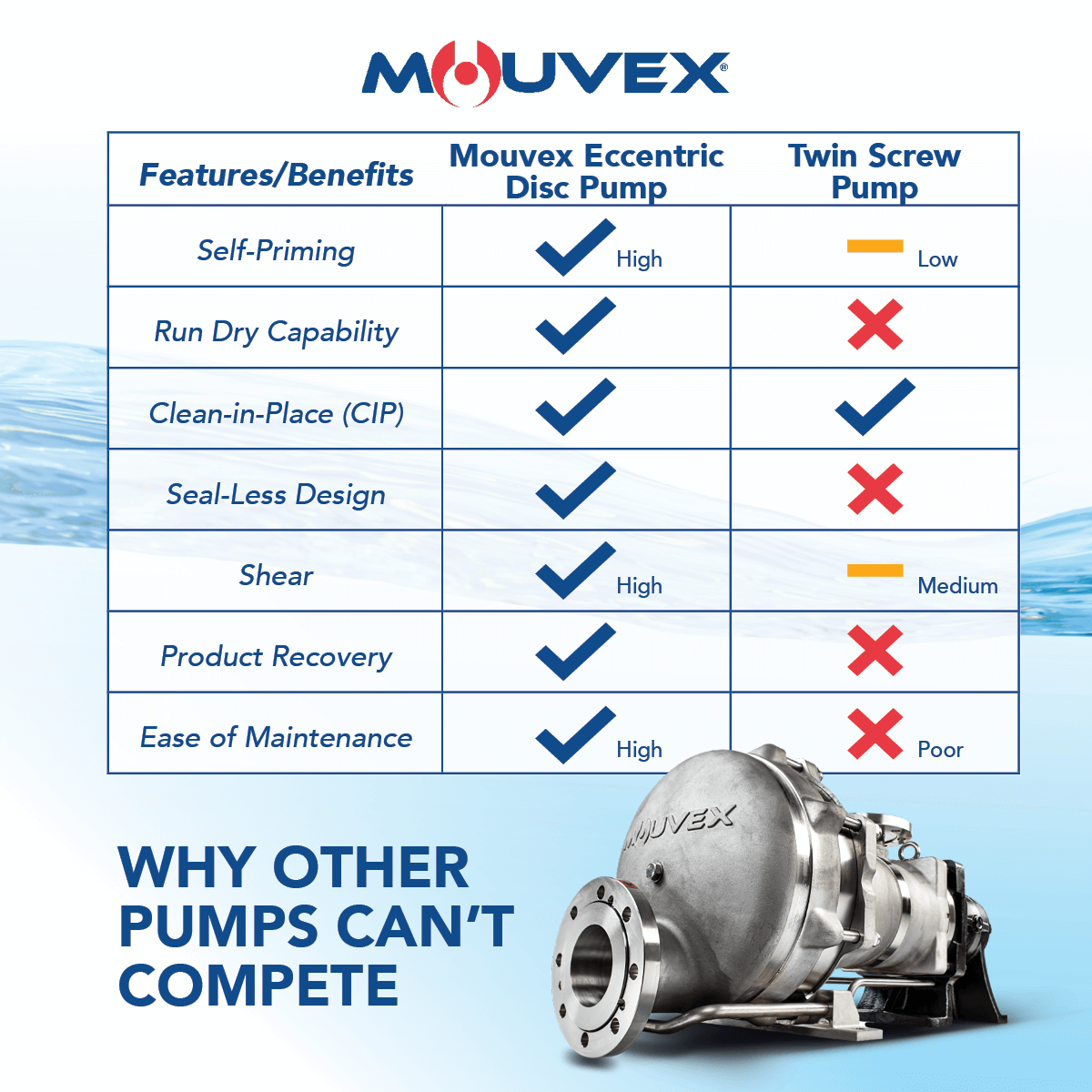

Twin screw pumps, although relatively low shear, can still degrade shear-sensitive materials and struggle with abrasive materials, resulting in compromised product quality. Additionally, twin screw pumps lack full product recovery, self-priming and dry-run capabilities. All of these factors lead to premature wear, increased maintenance and costly downtime.

At Mouvex, we've engineered a solution – the G-FLO Seal-Less Eccentric Disc Pump – to deliver the same benefits of screw pumps while eliminating the common drawbacks.