Mouvex G-FLO Eccentric Disc Pumps Vs. Lobe Pumps

Maximize Performance in Your Process

Eliminate Complexity, Maximize Performance

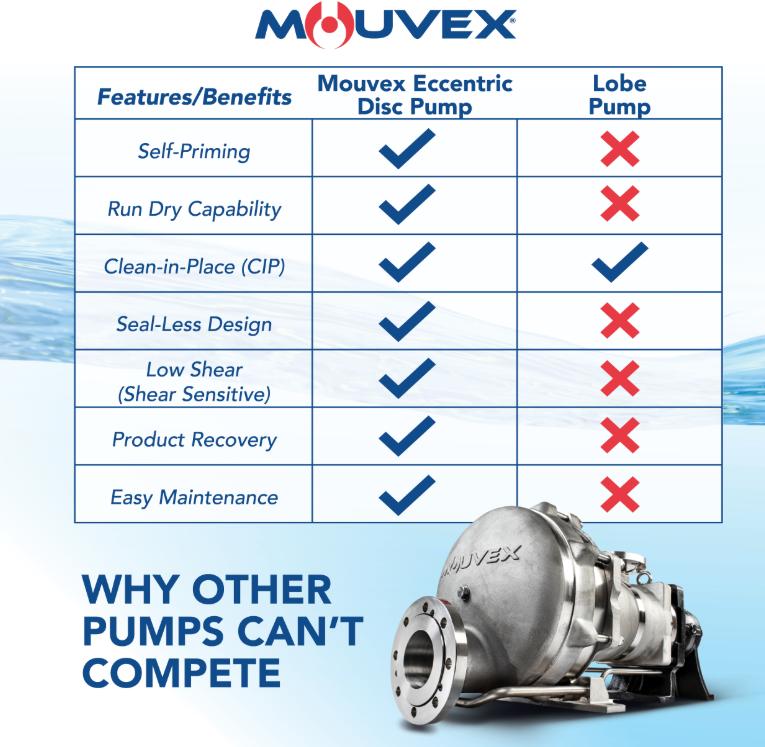

Lobe pumps can effectively handle high-viscosity fluids and solids, but their reliance on mechanical seals creates several challenges that prevent self-priming, limit dry-run capability and make them unsuitable for abrasive or sticky products. Moreover, mechanical seals are susceptible to misalignment, overheating and wear, resulting in high maintenance costs and potential leakage.

At Mouvex, we've redefined fluid transfer with the G-FLO Seal-Less Eccentric Disc Pump, which offers the benefits of lobe pumps while eliminating their most common drawbacks.