What Is the Best Efficiency Point (BEP)?

When it comes to centrifugal pumps, what is meant by the best efficiency point (BEP)? This target operating range is a pump’s sweet spot on the performance curve, a combination where flow and head rates are at ideal productivity. Operators can calculate and anticipate where a pump will function most efficiently using a formula or the performance curve.

Calculating BEP

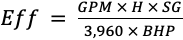

To illustrate the BEP for target pump operation, calculate pump efficiency based on head, flow, specific gravity and horsepower.

Using the sample formula above, operators can determine where the pump will perform at its highest level of efficiency. It’s helpful to confirm this optimal efficiency point visually on an evaluation (or performance) curve graph.

Comparing Operational Efficiencies

Testing pump performance in a lab setting best represents this difference in efficiencies. When you increase flow rate, gallons per minute rise, but head decreases, with a higher horsepower consuming more energy but not yielding better performance. In this case, efficiency will drop below BEP, falling to the right of the performance curve.

Decreasing the pump’s flow rate below the BEP, which reduces gallons per minute and causes head pressure to go up and power consumption to go down, again operating below efficiency.

Operating at BEP

As demonstrated, pump efficiency dramatically changes when you alter different factors of operation such as flow rate. Naturally, this affects system performance and productivity. By calculating and operating at the best efficiency point for your specific pump and application, you can optimize system performance. Learn more about pump operation and maintenance here.